A FULL SERVICE METAL STAMPING AND FABRICATION COMPANY

Español

"ACE - SERVICING OUR CUSTOMERS WITH VITAL CUSTOMER SATISFACTION, BY DELIVERING QUALITY, ON-TIME, COST-EFFICIENT PARTS AND SERVICES."

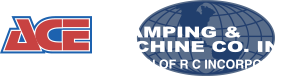

MODERN TOOL ROOM

All Tools Designed, Produced and Maintained In-House

Latest CAD/CAM Technology and Print Transfer by E-Mail

3D Modeling & CAD

Die Design / Repairs

Electronic Die Protection and Long Term Storage

Part Verification

Progressive, Secondary, Compound, Coining and Insert Stamping Dies

Low Cost Tooling and Tool Cost Reduction Programs

Comprehensive Manufacturing Support

Jigs and Fixtures Production

CNC Machining

High Precision Wire EDM Cutting

METAL STAMPING CAPABILITIES

76,000 Sq. Ft. Metal Stamping Facilities

40 Presses Ranging from 5 to 400 Tons

Progressive, Compound Blank and Secondary Stamping

Deep Draw Stampings up to 6"

Material Thickness between .002" & .500"

Low and High Volume Stamping into Millions

Stamping / Forming of Virtually any Alloy

Deep Draw Stampings up to 6"

Welding

Deburring

Finishing

Part Marking

Painting

Plating

FABRICATION SERVICES

30,000 Sq. Ft. Fabrication Facilities

In-house Design Engineering & Prototype Modeling

Single-Piece Construction

Mechanical / Electrical Assembly

Material Cutting

Material Forming

Press-In Hardware Insertion

Welding

Finishing

Part Marking

Painting

Plating

SECONDARY OPERATIONS

Drilling

Tapping

CNC Machining

Assembly

Hydraulic Inserting

Riveting

Welding

Deburring

Finishing

Part Marking

Painting

Plating

Special Packaging

ACE Stamping & Machine Co., Inc., ISO 9001 Certified, is a full-service Metal Stamping and Fabrication Company with multiple facilities located in Racine, Wisconsin USA (Corporate).

ACE has become an industry leader in the design and manufacturing of precision metal stampings and sheet metal fabrication, with an unlimited number of applications, including but not limited to, the automotive, oil & gas, agriculture, construction and medical industries. With over 50 years of experience, combined with staffed experts and utilizing state-of-the-art technology and procedures, we are able to manufacture the highest quality products alongside extremely competitive pricing.

With a full staff of engineers and an in-house full service tool room, ACE has the capabilities to handle virtually any metal stamping or sheet metal fabrication job in the industry. From designing high-level sheet metal assemblies to building the most complex progressive stamping dies, there is not a job that our engineers can't handle. As a result, capital expenses for both tooling and design are often reduced and sometimes eliminated.

Up-to-the-minute planning and procedures are implemented in every job from conception to delivery. With such hands-on approach, we are able to minimize or eliminate all unnecessary operations saving our customers both time and money.

From prototyping to the largest quantities, we want to help you. As a customer, we know how important it is for you to be able to rely on your supplier. That is why ACE has set the standard of reliability with a 98.5% on-time delivery rate.

We don't make you wait, we deliver!