A FULL SERVICE METAL STAMPING AND FABRICATION COMPANY

Español

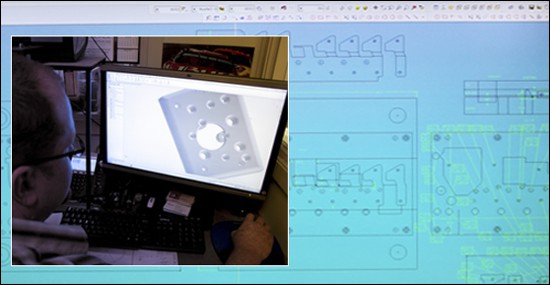

METAL STAMPING PROTOTYPE ENGINEERING

By utilizing an in-house tool room, ACE's talented design engineers are powered to design and manufacture virtually any type of metal stamping prototype to achieve our clients exact metal stamping specifications.

A prototype that's even a hair of a fraction off could be the difference between thousands of dollars and weeks of un-needed manufacturing for the client. Our engineering department carries out one of the highest-notable quality checks-n-balances in the industry.

Utilizing prototypes to DFM (design for manufacturability), our engineers are not only able to verify product accuracy, but plot the best coarse of manufacturing before the entire job goes into full production. If during a simulation run, weak spots are revealed, the prototype is re-designed resulting in improved manufacturability and cost savings.

"ACE - A PERFECT FIT FOR VIRTUALLY ANY PROTOTYPE NEEDS."

Whatever your needs are, ACE Metal Stamping is a 'perfect fit' for practically any prototyping requirement.

- Reverse Engineering

- Part Design

- 3D Printing

- Low Cost Tooling

- Short Run Production

Prototype tooling allows our engineers to test and validate each job prior to final tool manufacturing.